The company manufactures and stocks a wide range of Instrumentation Signal Cables needed for signaling systems, control and instrument circuits. Instrumentation Signal Cables report and monitor process variables ranging from transducers to environmental controls and computer inputs.

The carefully produced stranded copper conductors used in the Instrumentation Signal Cable maintain high system accuracy and sensitivity. Maximum rejection of electro magnetic noise is achieved by twisting the insulated conductors. Twisting causes the noise to be cancelled in adjacent sections of the wire.

Maximum electrostatic noise rejection is achieved by shielding the Instrumentation Signal Cable with aluminium-mylar tape. An overall shield is normally provided and in critical applications an individual shield over each pair or triad is also provided. A minimum of 25% overlap of the shield ensures 100% coverage even when the cable is flexed. The drain wire under the shield provides continuous low resistance path to ground and simplified hook-up at grounding terminals. The products can also be provided with copper braid screening.

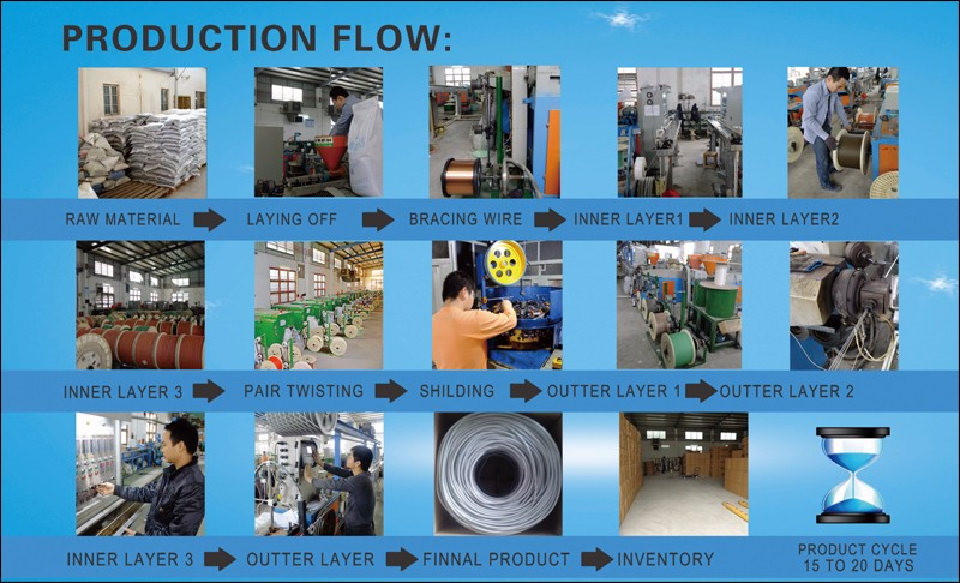

Production flow of Instrumentation Signal Cable

1.What is your delivery date?

A:The delivery date is about 5-7 days after receipt of payment.

2.What are your payment terms?

A:30% deposit in advance and 70% balance before shipment.

3.Can you send free samples?

A:Yes, free samples are available; you just need to pay the shipping cost.

Our usual packaging ways for Instrumentation Signal Cable are as followings, OR it can be as customer's request.